Understanding PE Film: Types, Uses, and Advantages

PE film is a versatile plastic material used in various industries, from food packaging to construction. This article will delve into the types of PE film available, their uses, and advantages. Discover why PE film is a popular choice for businesses and consumers alike.

What is PE Film? A Brief Overview

PE film stands for Polyethylene film, which is a versatile and widely used plastic film made from the thermoplastic polymer polyethylene. It is a thin, flexible, and lightweight material that is available in a variety of thicknesses and widths.

PE film is known for its high strength-to-density ratio, excellent moisture resistance, and durability. It is also resistant to chemicals and UV radiation, making it suitable for a range of applications, including packaging, agriculture, construction, and healthcare.

In the packaging industry, PE film is used for food packaging, retail bags, and industrial packaging. It is also used for agricultural applications, such as greenhouse covers, mulch films, and silage bags.

In the healthcare industry, PE film is used for medical packaging, such as surgical drapes and gowns, as well as for disposable gloves and other medical products.

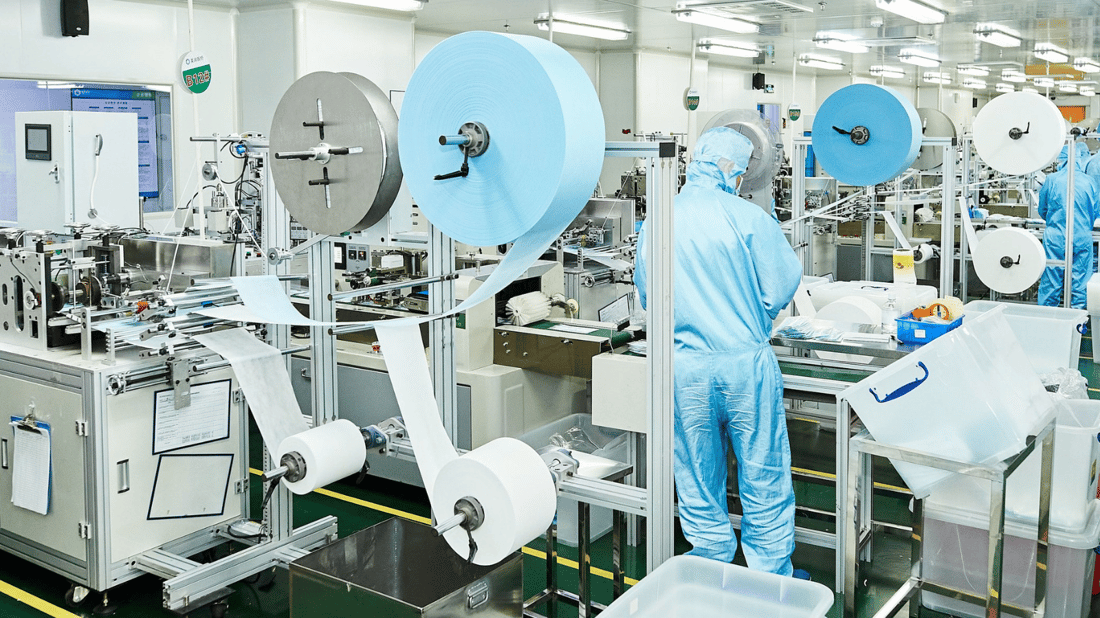

PE film can be produced using different manufacturing processes, including blown film extrusion and cast film extrusion. Blown film extrusion involves melting the plastic resin and blowing it into a bubble, which is then flattened and wound onto a roll. Cast film extrusion involves melting the plastic resin and casting it onto a chilled drum, which solidifies the film before it is wound onto a roll.

Overall, PE film is a versatile and widely used plastic film that offers a range of benefits, including high strength, moisture resistance, durability, and chemical and UV resistance.

Types of PE Film: A Comprehensive Guide

There are several types of PE film available, each with its own characteristics and properties. Here is a comprehensive guide to the different types of PE film:

-

Low-Density Polyethylene (LDPE) Film: LDPE film is a soft and flexible plastic film with good tear resistance and excellent clarity. It is commonly used in packaging, such as grocery bags, bread bags, and shrink wrap.

-

Linear Low-Density Polyethylene (LLDPE) Film: LLDPE film is a stronger and more puncture-resistant film than LDPE. It has good stretchability and is commonly used in stretch wrap, industrial bags, and agricultural films.

-

High-Density Polyethylene (HDPE) Film: HDPE film is a strong and stiff plastic film with good chemical resistance. It is commonly used in packaging for industrial products, such as detergents and chemicals, and in agricultural films.

-

Metallocene Polyethylene (mPE) Film: mPE film is a newer type of PE film that is made using metallocene catalysts. It has better puncture resistance, tear strength, and sealability than LDPE or LLDPE films. It is commonly used in packaging for food, medical, and industrial applications.

-

High Molecular Weight High-Density Polyethylene (HMW-HDPE) Film: HMW-HDPE film is a strong and stiff plastic film that is resistant to punctures and tears. It is commonly used in packaging for heavy-duty industrial products, such as hardware and construction materials.

-

Ultra High Molecular Weight Polyethylene (UHMW-PE) Film: UHMW-PE film is an extremely strong and abrasion-resistant plastic film that is commonly used in industrial applications, such as conveyor belt liners and chute linings.

Overall, there are many different types of PE film available, each with its own unique characteristics and properties. By understanding the different types of PE film, you can choose the right film for your specific application, whether it is for packaging, agriculture, healthcare, or industrial purposes.

The Many Uses of PE Film in Different Industries

PE film is a versatile plastic material that is widely used in various industries due to its many benefits, including flexibility, moisture resistance, chemical resistance, and durability. Here are some of the common uses of PE film in different industries:

-

Packaging Industry: PE film is widely used in the packaging industry for different applications. For instance, Low-Density Polyethylene (LDPE) is often used in plastic bags, shrink wrap, and bread bags, while Linear Low-Density Polyethylene (LLDPE) is used in stretch wrap, industrial bags, and agricultural films. High-Density Polyethylene (HDPE) film is used for packaging industrial products like detergents and chemicals.

-

Agriculture Industry: PE film is widely used in the agriculture industry for different applications. For instance, LDPE film is used to manufacture greenhouse covers, mulch films, and silage bags. LLDPE film is used in stretch wrap for palletized loads, while HDPE film is used to make irrigation pipes and water tanks.

-

Healthcare Industry: In the healthcare industry, PE film is used for medical packaging, such as surgical drapes and gowns, as well as for disposable gloves and other medical products. Metallocene Polyethylene (mPE) film, which has better puncture resistance, tear strength, and sealability, is commonly used in packaging for food, medical, and industrial applications.

-

Construction Industry: PE film is used in the construction industry for different applications. For instance, High Molecular Weight High-Density Polyethylene (HMW-HDPE) film is used for packaging heavy-duty industrial products like hardware and construction materials. Ultra High Molecular Weight Polyethylene (UHMW-PE) film is used as a lining material for conveyor belts, chutes, and hoppers, while LLDPE film is used as a moisture barrier for roofing and wall insulation.

-

Consumer Goods Industry: PE film is also used in the consumer goods industry for various applications like disposable diapers, sanitary napkins, and adult incontinence products.

Overall, PE film is a versatile and widely used plastic film that offers a range of benefits, making it suitable for different industries and applications. Its versatility makes it a preferred choice for manufacturers and consumers alike.

Advantages of Using PE Film over Other Materials

PE film offers several advantages over other materials, making it a popular choice for various applications. Here are some advantages of using PE film over other materials:

Lightweight and flexible: PE film is lightweight and flexible, making it easy to handle and transport. It can be folded, wrapped, and molded into different shapes and sizes, making it suitable for different packaging and industrial applications.

Moisture-resistant: PE film has excellent moisture resistance, making it ideal for packaging products that are sensitive to moisture, such as food, pharmaceuticals, and electronics.

Chemical-resistant: PE film has good chemical resistance, making it suitable for packaging and storing products that contain chemicals and other hazardous materials.

Durable: PE film is durable and has good tear resistance, making it suitable for heavy-duty packaging and industrial applications.

Cost-effective: PE film is a cost-effective material compared to other plastics like PVC, PET, and nylon. It is readily available and can be manufactured in large quantities, making it an affordable option for different applications.

Recyclable: PE film is a recyclable material, making it an environmentally friendly option for packaging and industrial applications.

Versatile: PE film can be made in different types, such as LDPE, LLDPE, and HDPE, to suit different applications. It can also be made with different additives, such as UV stabilizers, anti-static agents, and slip agents, to enhance its properties and performance.

Overall, PE film offers several advantages over other materials, making it a preferred choice for different applications in various industries. Its versatility, durability, and cost-effectiveness make it a popular material for packaging and industrial applications.

How to Choose the Right PE Film for Your Business Needs

Choosing the right PE film for your business needs can be challenging, considering the many types of PE film available in the market. Here are some factors to consider when choosing the right PE film for your business needs:

Application: The first step in choosing the right PE film is to identify the application. What is the intended use of the film? For instance, is it for packaging food, pharmaceuticals, or industrial products? Different types of PE film are designed for different applications, so it's essential to choose the right type for the intended use.

Thickness: PE film comes in different thicknesses, ranging from 0.5 mils to over 10 mils. The thickness of the film determines its strength and durability, so it's essential to choose the right thickness for the intended use.

Type of PE Film: PE film comes in different types, such as LDPE, LLDPE, HDPE, and mPE. Each type has its properties and performance characteristics, so it's essential to choose the right type based on the intended use.

Additives: PE film can be made with different additives, such as UV stabilizers, anti-static agents, and slip agents. These additives can enhance the film's properties and performance, depending on the intended use. For instance, UV stabilizers can protect the film from UV degradation, while slip agents can reduce friction between the film layers.

Color: PE film can be made in different colors, depending on the intended use. For instance, green and black LDPE film is commonly used as mulch film in agriculture, while clear LLDPE film is used for packaging products that require visibility.

Roll Size: The size of the roll can vary depending on the manufacturer and intended use. It's essential to choose the right roll size based on the quantity required and the storage space available.

Overall, choosing the right PE film requires careful consideration of the application, thickness, type, additives, color, and roll size. Consulting with a reputable PE film supplier can help in identifying the right type of PE film for your business needs.